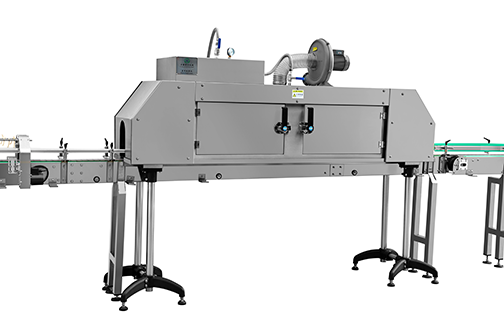

SRL-150 Shrink Sleeve Applicator Machine was made of high quality stainless steel material, the electricity and machine structure are improved, so it has more stable performance. This model meets 9000 bottle/hour production requirements.

It is suit for labeling of round bottle, square bottle, bottle body and bottle neck etc.

The electric shrink tunnel in the subsequent streamline shrinks the sleeve labels by the form of electrical heating, the surface of the products have no droplet steam, can be packed directly, this product is mainly used in moisture-proof and damp-proof products.

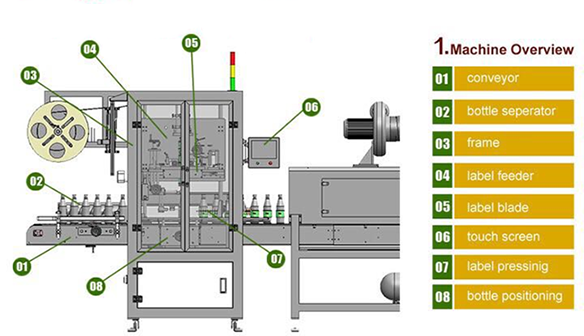

1. Adopt original Mitsubishi motor and PLC. STABLE & DURABLE performance.

2. Mitsubishi/Siemens touch screen efficient operation.

3. Easy change cutting knife mechanism.

4. Wide application range for varied bottle and label specifications. Easy adjustment on mandrel.

5. SICK label sensor. Optional for transparent labels.

6. Stable label feeding and the feeding motion won't affect the production performance.

|

Machine Model |

SRL-150 |

|

Max Speed [bottles/min] |

150 |

|

Electrical Consumption |

3.5Kw |

|

Comp. Air pressure/consumption |

- |

|

Cutting Knife Plates Ranges |

025-050 / 051~090mm/ 091~0125mm(can be designed) |

|

Bottle Diameters Ranges |

025mm to 0125mm (can be designed) |

|

Standard bottle Height |

approx. 3500mm (can be designed) |

|

Standard Cut Length |

approx. 25mm ~ 300mm (longer CL to be confirmed) |

|

Lay Flat ranges |

43mm ~ 200mm |

|

Bottle Materials |

PET, PVC, GLASS, METAL, HDPE, PP, PS |

|

Label Materials |

PVC, PET & OPS |

|

Labeling Types |

Full Body, Middle Body, Overall, Shoulder, Cap Seal |

|

Labels Thickness |

0.035mm ~ 0.080mm |

|

Roll Inner Core Diameter |

5” to 10” |

|

Machine Base Dimensions |

900mm Length x 860mm Width x 1600mm Height |

|

Net Weight of machine |

approx. 500Kgs |