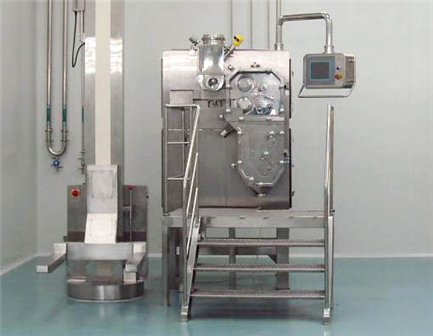

RC Roller Compactor is a high-efficiency granulating equipment, especially for thermosensitive and humidity sensitive products.

The two-stage mill sieves are 20~30 mesh sizes, granulation pass rate ≥ 80% (standard placebo of starch and sugar).

Fine powder content 8~10%.

Within 15 minutes to disassemble front parts for cleaning, which can be done without any special tool.

Dry granulation is easy to process and without a physical change to materials. It is widely used in the pharmaceutical industry, chemical, and foodstuff industries.

High automation, continuous processing.

Fine powder collected for recycling.

Through-the-wall installation.

Different roller patterns for the option.

Processing area and driving area reasonably isolated.

Front processing parts are easy to dismantle for cleaning.

Controlled dust release, no cross contamination.

| Model | RCS40 | RC70 | RC100 | RC200 |

| Capacity [kg/h] | 40 | 70 | 100 | 200 |

| Output Particle Size [mesh] | 15~60 | 15~60 | 15~60 | 15~60 |

| Roller Pressure [t/cm²] | 4 | 4 | 5 | 5 |

| Power [kW] | 11.5 | 13.5 | 18.5 | 21.6 |

| Dimensions [mm] | 1100x1000x1600 | 1200x1000x1880 | 1445x1400x1982 | 1600x1530x2100 |

| Machine Weight [kg] | 700 | 900 | 1100 | 2000 |