The machine is suitable for dry powder mixing and direct discharge, which is widely used in pharmaceutical, food and chemical industries.

1. The machine is mainly Stainless Steel 304/316L material structure. Machine outside surface satin finished, inside surface and paddles are mirror polished.

2. Common batch mixing time is within 180 seconds, mixing uniformity reaching 95%.

3. Designed maintenance access door for maintenance and cleaning. The access door has the safety lock to ensure operator safety.

4. Mixing shaft sealing is ensured by air seal, ensuring no leakage or pollution in the shaft.

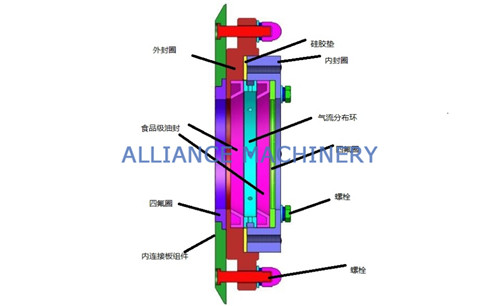

5. Shaft sealing

Mixing shaft mechanical sealing + air purge sealing from a shaft.

Avoid cross-contamination.

Options

1. Solution adding

- Add solution through hopper from top material inlet door.

- By peristaltic pump/compressed air nozzles spray at top material inlet door.

2. Cutting system

Cutting system is usually required when products will be packed directly after peddle mixer, without further processing.

The cutting system breaks large granule bulks formed during mixing, resulting in more uniform and easy handling finished products.

|

Machine Model |

YTGH 500 |

|

|

Working Volume [L] |

500 |

|

|

Batch Size [kg/batch] |

75-250 (based on bulk density 0.5) |

|

|

Mixing Time [s/batch] |

90-180 |

|

|

Mixing Speed [rpm] |

53 |

|

|

Stirring Peddle Motor [kW] |

7.5 |

|

|

Mixing Uniformity |

≥95% |

|

|

Cutter Motor [kW] |

3 |

|

|

Cutter Speed [rpm] |

50~3000 |

|

|

Compressed Air Consumption [L/h] |

600 |

|

|

Compressed Air |

Pressure [MPa] |

0.6 |

|

Cleanliness |

Dew point below 0oC, particle size ≤ 0.3μm, oil content ≤ 0.8ppm |

|