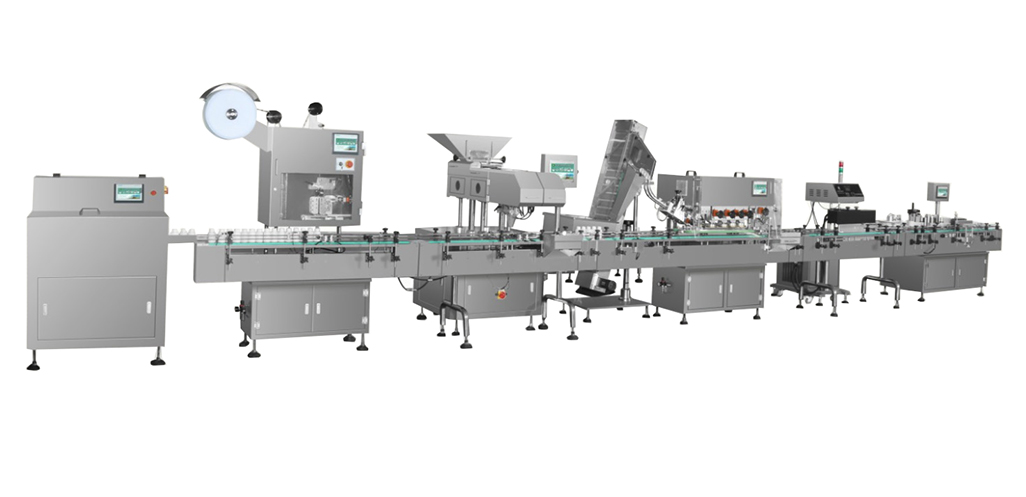

The production line include rotary table, desiccant inserter, counting machine, induction sealer, labeling machine.

Rotary table

The machine needs o put bottles on a rotary table manually by operator and the bottles will automatically enter into the conveyor belt of the next machine. The disadvantage of the machine is that one operator is needed to put bottles by hand, compared with the high-speed unscrambling machine. Rotary Type Bottle Unscrambling Machine is used in small output enterprises, which manufacture healthy products of multiple bottle specification and single variety.

Features

Easy to operate, simple to repair and stable to work

Rack and plate use stainless steel material, aesthetic in appearance.

Desiccant inserter

SLGZ-200 High-speed Dryer Inserting Machine is suitable for all type of bottles, bottle height, size and cap diameter can be adjusted—no change parts are needed! The coil is pulled apart into desired lengths through two pairs of pinch rollers, each piece is the folded and inserted up into a tube, the tube then moves over the bottle and the cotton piece is inserted to the air cylinder. It can work independently or can be integrated with the packaging line. Automatic stops function for open-door, will guarantee safety of operator. Pre-programming system control helps easy operate showing all parameters on the interface panel.

Features

Applicable to all size of desiccant.

Equipped with alarm system when no desiccant or desiccant jam.

Color mark detection and photoelectric control makes easier to operate.

Equipped with protective device that stops automatically not proper positioned and will adjust position prior to filling for 100% accuracy.

Adopts automatic variety frequency controlled system to allow speed regulation, avoiding the problem of inflexibility.

Optional language interface and PLC control system provide easy access to all settings within the range of parameters.

The electrical counting machine stops when the desiccant inserting machine stops, and it resumes working when the desiccant insertion machine works.

Electrical counting machine

The machine with 8//12/16/24 channels, dual feeder and two stage DC

variable frequency vibration control system. No need mold for counting any size

of the pill.

Feature

Integral closed type structure design.

Adaptive feeding speed regulation system

Working status detection and fault alarm function is available.

No blind infrared photoelectric detection screen

Photoelectric sensor has dust control and self diagnosis function, to ensure accuracy of counting tablets.

Has function of eliminating lamination and debris,

Lack of bottle of photoelectric sensor automatically detection,

Two stage DC variable frequency vibration control system provides a stable and fast driving for counting tablets.

Dust removal system eliminates the influence to photoelectric sensor

Designed with preset counting, it can advance speed of counting.

Large and small hopper matched with bottling, improved the speed of bottling.

Bottle feeding mouth can cover bottle neck automatically, avoiding short medicine grain of jumping out of the bottle.

Auto elevating construction is convenient to adjust the height of hopper suitable with different bottle.

Main parts are tool-less to dismantle and clean, quick changeover.

Automatic in-line capper

Automatic In-Line Capper is applicable for round, rectangular and most irregular bottle, and it can be adjusted to different caps diameters and height without changeover of new parts. An optional large capacity floor level cap hopper to stock caps for long runs without continual refilling can be added. The cap chute is adjustable for different size of caps. Unique design requires on changeover parts and no tools when changing caps sizes. Four Hand wheels with digital indicators are for quick and easy adjustments. A cap chute sensor is provided to detect caps in caps chute in correct direction by gravity. The cap elevator will stop automatically when the cap chute is full. A safety guard surrounds cap lightening station for operator’s safety. A fail safe dual inspection system removes incorrectly oriented caps from loading chute.

Feature

Sensor detection and rejection system.

Variable Speed Control

Snap-on Capping System can be integrated into this unit for dual applications.

Adopts high elastic wear-resisting rubber wheel, screw cap wheel, and clamp bottle conveyor that has variable speed regulation.

As adopts gear case transmission.

Cap unscrewing and clamp adjusting have digital display device makes them easy to operate.

Noise level: ≤65db

Automatic induction sealer

The electro-magnetic induction aluminum foil sealing machine utilizes the principle of electromagnetic induction to obtain hermetic sealing by making the surface of aluminum foil instantaneously heat to adhere tightly on mouth of bottle. The machine is suitable for sealing all type of products in many industries such as pharmaceutical, food, pesticide, petroleum, cosmetics, chemical and other applications to obtain the highest sealing quality to increase the shelve life of the products and for child resistant safety purposes.

Feature

Most affordable automatic induction sealer in the industry.

Composite aluminum foil for sealing is also acceptable.

Includes Sanitary conveyor.

Available Foil Detecting & Rejecting System

Featuring of tunnel type inductor makes it seal fast and stable.

Sensor head is adjustable for suitable to different height of the container seal packing.

Sensor head use bold copper tube, built-in water circulation system, reduce the cost.

Sealing process quickly and efficiently, bottle even with a small amount of water or residual liquid can be sealed effectively as well.

Fully modular intellectualized design are built to resist moisture, corrosion, dust and magnetic. Long life and low failure rate, and easy for repair

Alarm sounds automatically when they detect water shortage in tank, over high water temperature and breakdown.

Water cooling system to keep the constant temperature condition for long time working.

The host generator uses the latest importer transistor, CPU modular control.

The host and tank separate design, easy to maintain. With the same type of sensing head.

Equipment noise level: ≤50 db

Automatic labeling machine

The Automatic Labeler with accumulation tray is very easy for operate. Touch screen control technology labeler length, lot number stamping and conveyor speed can be set and adjust. Automatic sensor, troubleshooting and data display works more efficient and stable. Custom built labelers available for square bottles, both side labeler and top labeler, can also work along with hot stamp printer.

Feature

Suitable for various round bottle surface labeling

It adopts infinitely variable speed control, not necessary to move sensor eye conveying and labeling.

This machine integrates electrical and mechanical device, with simple and reasonable structure and several protective devices. It is easy to maintain.

It is equipped with interface and PLC control system of convenient operation, easy maintenance and steady performance, providing easy access to all settings within the range of parameters.

It has automatic control and detects system to stop in case of missing bottles, labels and bottle jams, reserved bottles and running out of ribbon.

It adopts opto-electrical system to paste labels, with steady performance. The label position can be adjusted arbitrarily.

The machine has heat code printer for distinct printing of 360 angles.